Made of high-quality silicon steel sheet, H grade enameled wire and comes with low temperature rise, low loss, low noise, strong overload capacity

It adopts fully automatic vacuum pressure impregnation technology, with strong anti-corrosion ability and more stable electrical performance

With secondary protection temperature control switch to ensure high safety

To meet the higher requirements of users, a large number of nonlinear loads are widely used in the current power system. The resulting power quality problems are becoming more and more prominent, problems such as harmonic interference and voltage distortion not only lead to abnormal operation of electrical equipment, but even direct damage. These phenomena can be effectively improved or avoided by series reactors in reactive power compensation system.

Lafaelt detuned reactor is used in the low-voltage power compensation cabinet and is connected in series with power factor correction capacitor. When there are a large number of harmonic sources such as rectifiers and converter devices in the low-voltage grid, the high-order harmonic generated by it will seriously damage the safe operation of the main transformer and other electrical devices. After the reactor is connected with the capacitor in series, it can absorb the grid harmonics effectively, improve the voltage waveform and increase the power factor of the system, and can effectively suppress the clothing inrush current and operating overvoltage, it can protect the capacitor effectively.

1. The iron core is made of high-quality low-loss cold rolled oriented silicon steel sheet. The pillar of the core is split into small, even sections by numerous air vents. The gaps use an epoxy layer of glass cloth panels to form intervals, ensuring that the reactance of the gaps does not change during operation.

2. The solenoids use a tightly packed and uniform Class H flat copper wiring system. It boasts an exceptional fine appearance and an excellent ability to dissipate heat.

3. The solenoids and iron core are assembled into one and go through the process of pre-baking vacuum impregnation, heat curing, and solidification.

4. The partial fasteners of the core column are made of non-magnetic materials to make a better filtering effect. The exposed parts are all treated with an anti-corrosion process and the lead-out terminals are made of tin-plated copper tube.

5. The reactor has the advantages of small size, light weight, beautiful appearance, etc.

In order to facilitate the air circulation of the upper and lower floors, capacitors and reactors need to be installed on mental brackets, do not use a whole board for installation. (Mounting plate with heatsink holes can be used)

When installing, keep the capacitor away from reactor as much as possible. When installed on upper and lower layers, the capacitor should be placed on the lower layer of the reactor.

If they must be installed on the same floor, the distance between the capacitor case and the reactor should be ≧100mm

When connecting the cables, pay attention that not carry the iron core and other heating parts of the reactor on the cables to prevent the cables from burning.

Implementing Standards | GB/T1094.6-2011 | |

Application Environment | ||

Temperature | -20°C~+40℃ | |

Altitude | ≦2000m (Higher altitude can customized) | |

Relative Humidity | ≦95% | |

Electrical Parameters | ||

Overvoltage | 1.35 times | |

Insulation Level | H Level | |

Pressurizaion Level | ≧4kV between each coil and ground | |

Noise | ≦40dB | |

Lt Inductance Deviation | ±3%Ln | |

Reactor Linearity | 1.8ln(higher can be designed), L>0.95 | |

Common Reactance Ratio | 5%, 5.67%, 7%, 12.5%, 14%, etc. | |

Operating Parameters | ||

Working Voltage | <1000V Power System | |

Rated Frequency | 50Hz or 60Hz | |

Maximum overcurrent allowable value | 2.1ln | |

Maximum Surge | 100ln | |

Reliability/Protective | ||

Temperature Protection | +125°C Overheating disconnection (Normally Closed) (Others can be customized) | |

Protection Level | IP00,Install indoor | |

Flame retardant grade | V0 | |

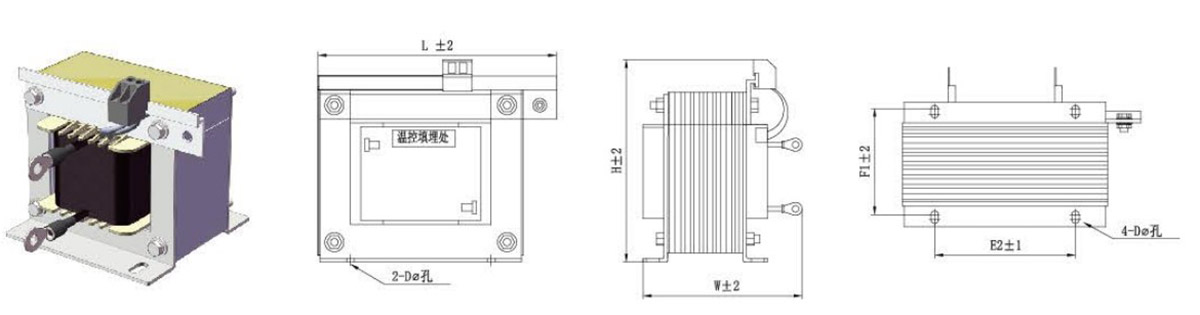

Mode | Capacity | Reactance Ratio | Dimensions | Installation Size | |||

(kvar) | % | L | W | H | E | F | |

LDR280-6.7-7 | 6.7 | 7% | 158 | 192 | 148 | 93 | 105 |

LDR280-8.3-7 | 8.3 | 7% | 158 | 192 | 148 | 93 | 105 |

LDR280-10-7 | 10 | 7% | 158 | 192 | 148 | 93 | 105 |

LDR280-13.4-7 | 13.4 | 7% | 185 | 210 | 162 | 115 | 110 |

LDR280-15-7 | 15 | 7% | 185 | 210 | 162 | 115 | 110 |

LDR280-16.7-7 | 16.7 | 7% | 185 | 210 | 162 | 115 | 110 |

LDR280-20-7 | 20 | 7% | 185 | 240 | 162 | 115 | 135 |

LDR300-6.7-14 | 6.7 | 14% | 185 | 210 | 162 | 115 | 110 |

LDR300-8.3-14 | 8.3 | 14% | 185 | 210 | 162 | 115 | 110 |

LDR300-10-14 | 10 | 14% | 185 | 240 | 162 | 115 | 135 |

LDR300-13.4-14 | 13.4 | 14% | 215 | 270 | 200 | 145 | 155 |

LDR300-15-14 | 15 | 14% | 215 | 270 | 200 | 145 | 155 |

LDR300-16.7-14 | 16.7 | 14% | 215 | 270 | 200 | 145 | 155 |

LDR300-20-14 | 20 | 14% | 215 | 270 | 200 | 145 | 155 |

(The outline drawing of single-phase detuned reactor)

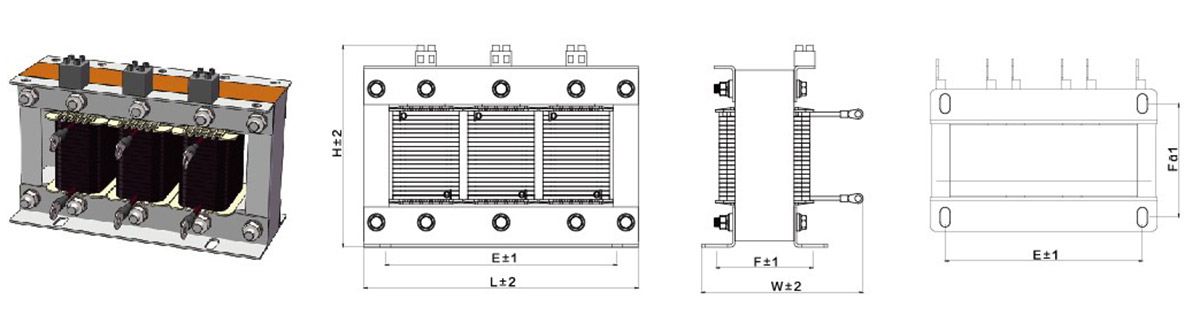

Mode | Capacity | Reactance Ratio | Dimensions | Installation Size | |||

(kvar) | % | L | W | H | E | F | |

LDR280-20-7F | 20 | 7% | 263 | 168 | 184 | 219 | 95 |

LDR280-25-7F | 25 | 7% | 278 | 174 | 204 | 235 | 100 |

LDR280-30-7F | 30 | 7% | 278 | 174 | 204 | 235 | 100 |

LDR280-40-7F | 40 | 7% | 298 | 183 | 211 | 252 | 105 |

LDR280-45-7F | 45 | 7% | 330 | 195 | 221 | 286 | 115 |

LDR280-50-7F | 50 | 7% | 330 | 195 | 221 | 286 | 115 |

LDR280-60-7F | 60 | 7% | 330 | 195 | 256 | 286 | 115 |

LDR300-20-14F | 20 | 14% | 298 | 183 | 211 | 252 | 105 |

LDR300-25-14F | 25 | 14% | 330 | 195 | 256 | 286 | 115 |

LDR300-30-14F | 30 | 14% | 330 | 195 | 256 | 286 | 115 |

LDR300-45-14F | 45 | 14% | 350 | 215 | 280 | 300 | 145 |

LDR300-50-14F | 50 | 14% | 350 | 215 | 280 | 300 | 145 |

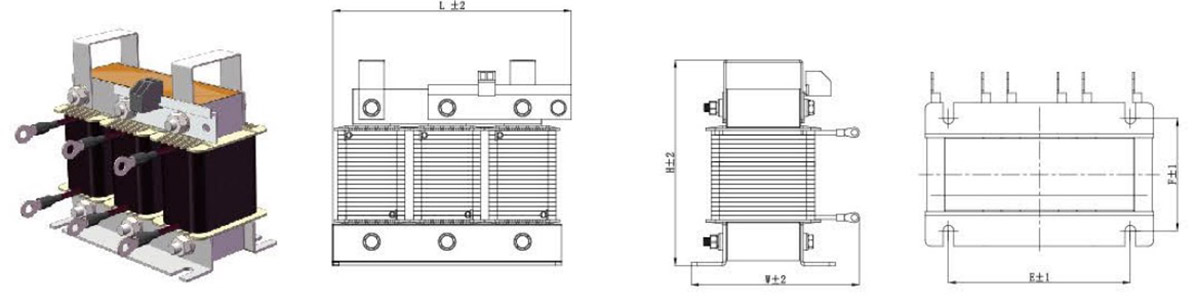

Mode | Capacity | Reactance Ratio | Dimensions | Installation Size | |||

(kvar) | % | L | W | H | E | F | |

LDR440-15-7 | 15 | 7% | 215 | 170 | 200 | 170 | 100 |

LDR440-20-7 | 20 | 7% | 215 | 170 | 200 | 170 | 100 |

LDR440-25-7 | 25 | 7% | 240 | 190 | 210 | 183 | 110 |

LDR440-30-7 | 30 | 7% | 240 | 190 | 210 | 183 | 110 |

LDR440-40-7 | 40 | 7% | 245 | 190 | 220 | 183 | 110 |

LDR440-50-7 | 50 | 7% | 290 | 210 | 270 | 200 | 115 |

LDR440-60-7 | 60 | 7% | 290 | 210 | 270 | 200 | 115 |

LDR480-10-7 | 10 | 7% | 215 | 170 | 200 | 170 | 100 |

LDR480-15-7 | 15 | 7% | 215 | 170 | 200 | 170 | 100 |

LDR480-20-7 | 20 | 7% | 215 | 170 | 200 | 170 | 100 |

LDR480-25-7 | 25 | 7% | 240 | 190 | 210 | 183 | 110 |

LDR480-30-7 | 30 | 7% | 240 | 190 | 210 | 183 | 110 |

LDR480-33.4-7 | 33.4 | 7% | 245 | 190 | 220 | 183 | 110 |

LDR480-40-7 | 40 | 7% | 245 | 190 | 220 | 183 | 110 |

LDR480-50-7 | 50 | 7% | 290 | 210 | 235 | 200 | 115 |

LDR480-60-7 | 60 | 7% | 290 | 210 | 270 | 200 | 115 |

LDR480-67-7 | 67 | 7% | 290 | 210 | 270 | 200 | 115 |

LDR525-15-14 | 15 | 14% | 240 | 190 | 210 | 183 | 110 |

LDR525-20-14 | 20 | 14% | 290 | 210 | 235 | 200 | 115 |

LDR525-25-14 | 25 | 14% | 290 | 210 | 235 | 200 | 115 |

LDR525-30-14 | 30 | 14% | 290 | 210 | 235 | 200 | 115 |

LDR525-40-14 | 40 | 14% | 300 | 240 | 300 | 210 | 145 |

LDR525-50-14 | 50 | 14% | 300 | 240 | 300 | 210 | 145 |

LDR525-60-14 | 60 | 14% | 300 | 240 | 300 | 210 | 145 |

LDR850-25-7 | 25 | 7% | 290 | 210 | 235 | 200 | 115 |

LDR850-30-7 | 30 | 7% | 290 | 210 | 235 | 200 | 115 |

LDR850-50-7 | 50 | 7% | 300 | 240 | 300 | 210 | 145 |

LDR850-60-7 | 60 | 7% | 300 | 240 | 300 | 210 | 145 |

Mode | Capacity | Reactance Ratio | Dimensions | Installation Size | |||

(kvar) | % | L | W | H | E | F | |

LDR-H-280-10-7 | 10 | 7% | 158 | 192 | 148 | 93 | 105 |

LDR-H-280-15-7 | 15 | 7% | 185 | 210 | 162 | 115 | 110 |

LDR-H-280-20-7 | 20 | 7% | 185 | 240 | 162 | 115 | 135 |

LDR-H-300-10-14 | 10 | 14% | 185 | 240 | 162 | 115 | 135 |

LDR-H-300-15-14 | 15 | 14% | 215 | 270 | 200 | 145 | 155 |

LDR-H-300-20-14 | 20 | 14% | 215 | 270 | 200 | 145 | 155 |

Mode | Capacity | Reactance Ratio | Dimensions | Installation Size | |||

(kvar) | % | L | W | H | E | F | |

LDR-H-480-15-7 | 15 | 7% | 215 | 170 | 200 | 170 | 100 |

LDR-H-480-20-7 | 20 | 7% | 215 | 170 | 200 | 170 | 100 |

LDR-H-480-25-7 | 25 | 7% | 240 | 190 | 210 | 183 | 110 |

LDR-H-480-33.4-7 | 33.4 | 7% | 245 | 190 | 220 | 183 | 110 |

LDR-H-480-30-7 | 30 | 7% | 240 | 190 | 210 | 183 | 110 |

LDR-H-480-40-7 | 40 | 7% | 245 | 190 | 220 | 183 | 110 |

LDR-H-480-50-7 | 50 | 7% | 290 | 210 | 235 | 200 | 115 |

LDR-H-480-60-7 | 60 | 7% | 290 | 210 | 270 | 200 | 115 |

LDR-H-480-67-7 | 67 | 7% | 290 | 210 | 270 | 200 | 115 |

LDR-H-525-15-14 | 15 | 14% | 240 | 190 | 210 | 183 | 110 |

LDR-H-525-20-14 | 20 | 14% | 290 | 210 | 235 | 200 | 115 |

LDR-H-525-25-14 | 25 | 14% | 290 | 210 | 235 | 200 | 115 |

LDR-H-525-30-14 | 30 | 14% | 290 | 210 | 235 | 200 | 115 |

LDR-H-525-40-14 | 40 | 14% | 300 | 240 | 300 | 210 | 145 |

LDR-H-525-50-14 | 50 | 14% | 300 | 240 | 300 | 210 | 145 |

LDR-H-525-60-14 | 60 | 14% | 300 | 240 | 300 | 210 | 145 |

Mode | Capacity | Reactance Ratio | Dimensions | Installation Size | |||

(kvar) | % | L | W | H | E | F | |

LDR-S-280-6.7-7 | 6.7 | 7% | 158 | 192 | 148 | 93 | 105 |

LDR-S-280-8.3-7 | 8.3 | 7% | 158 | 192 | 148 | 93 | 105 |

LDR-S-280-10-7 | 10 | 7% | 158 | 192 | 148 | 93 | 105 |

LDR-S-280-13.4-7 | 13.4 | 7% | 185 | 210 | 162 | 115 | 110 |

LDR-S-280-15-7 | 15 | 7% | 185 | 210 | 162 | 115 | 110 |

LDR-S-280-16.7-7 | 16.7 | 7% | 185 | 210 | 162 | 115 | 110 |

LDR-S-280-20-7 | 20 | 7% | 185 | 240 | 162 | 115 | 135 |

LDR-S-300-6.7-14 | 6.7 | 14% | 185 | 210 | 162 | 115 | 110 |

LDR-S-300-8.3-14 | 8.3 | 14% | 185 | 210 | 162 | 115 | 110 |

LDR-S-300-10-14 | 10 | 14% | 185 | 240 | 162 | 115 | 135 |

LDR-S-300-13.4-14 | 13.4 | 14% | 215 | 270 | 200 | 145 | 155 |

LDR-S-300-15-14 | 15 | 14% | 215 | 270 | 200 | 145 | 155 |

LDR-S-300-16.7-14 | 16.7 | 14% | 215 | 270 | 200 | 145 | 155 |

LDR-S-300-20-14 | 20 | 14% | 215 | 270 | 200 | 145 | 155 |

Mode | Capacity | Reactance Ratio | Dimensions | Installation Size | |||

(kvar) | % | L | W | H | E | F | |

LDR-S-280-20-7F | 20 | 7% | 263 | 168 | 184 | 219 | 95 |

LDR-S-280-25-7F | 25 | 7% | 278 | 174 | 204 | 235 | 100 |

LDR-S-280-30-7F | 30 | 7% | 278 | 174 | 204 | 235 | 100 |

LDR-S-280-40-7F | 40 | 7% | 298 | 183 | 211 | 252 | 105 |

LDR-S-280-45-7F | 45 | 7% | 330 | 195 | 221 | 286 | 115 |

LDR-S-280-50-7F | 50 | 7% | 330 | 195 | 221 | 286 | 115 |

LDR-S-280-60-7F | 60 | 7% | 330 | 195 | 256 | 286 | 115 |

LDR-S-300-20-14F | 20 | 14% | 298 | 183 | 211 | 252 | 105 |

LDR-S-300-25-14F | 25 | 14% | 330 | 195 | 256 | 286 | 115 |

LDR-S-300-30-14F | 30 | 14% | 330 | 195 | 256 | 286 | 115 |

LDR-S-300-45-14F | 45 | 14% | 350 | 215 | 280 | 300 | 145 |

LDR-S-300-50-14F | 50 | 14% | 350 | 215 | 280 | 300 | 145 |

Mode | Capacity | Reactance Ratio | Dimensions | Installation Size | |||

(kvar) | % | L | W | H | E | F | |

LDR-S-480-15-7 | 15 | 7% | 215 | 170 | 200 | 170 | 100 |

LDR-S-480-20-7 | 20 | 7% | 215 | 170 | 200 | 170 | 100 |

LDR-S-480-25-7 | 25 | 7% | 240 | 190 | 210 | 183 | 110 |

LDR-S-480-30-7 | 30 | 7% | 240 | 190 | 210 | 183 | 110 |

LDR-S-480-33.4-7 | 33.4 | 7% | 245 | 190 | 220 | 183 | 110 |

LDR-S-480-40-7 | 40 | 7% | 245 | 190 | 220 | 183 | 110 |

LDR-S-480-50-7 | 50 | 7% | 290 | 210 | 235 | 200 | 115 |

LDR-S-480-60-7 | 60 | 7% | 290 | 210 | 270 | 200 | 115 |

LDR-S-480-67-7 | 67 | 7% | 290 | 210 | 270 | 200 | 115 |

LDR-S-525-15-14 | 15 | 14% | 240 | 190 | 210 | 183 | 110 |

LDR-S-525-20-14 | 20 | 14% | 290 | 210 | 235 | 200 | 115 |

LDR-S-525-25-14 | 25 | 14% | 290 | 210 | 235 | 200 | 115 |

LDR-S-525-30-14 | 30 | 14% | 290 | 210 | 235 | 200 | 115 |

LDR-S-525-40-14 | 40 | 14% | 300 | 240 | 300 | 210 | 145 |

LDR-S-525-50-14 | 50 | 14% | 300 | 240 | 300 | 210 | 145 |

LDR-S-525-60-14 | 60 | 14% | 300 | 240 | 300 | 210 | 145 |

| Classify | Title | Download |

|---|---|---|

| Antidr Reactor Operation Manual V1.1 |

Leave your contacts and our engineers will help you to find the solution you are looking for.

Hi! Welcome back.

How are you doing?

Let s talk! We’ll provide the perfect solution for you!

Since its establishment, Lafaelt Electric has focused on comprehensive solutions for power quality and energy management. It has excellent quality in designing, researching, producing and manufacturing.

Sales Center Add: 2nd Floor, No. 268, Tongxie Road, Changning District, Shanghai, China

Factory Add:No. 79, Qunxing Road, Xinwu District, Wuxi City, Jiangsu Province, China