The base film is made of TREOFAN ultra-high temperature resistance material imported from Germany

Unique evaporation formula process ensuring better performance

The world's first original design with explosion-proof and temperature control in one

Lafaelt Electirc emphasizes on the production technology and eco-friendly concept, by adopting unique professional technology and accumulated experience in capacitor manufacturing for many years, it has successfully developed Esicap eco-friendly self-healing capacitor. The Esi eco-friendly self-healing capacitor technology refer to the use of vacuum nitrogen-filled heat setting process and dry insulating filling materials in the process of capacitor production to ensure the performance stability and eco-friendly of the capacitor. This technology has been the symbol of the Esicap capacitor.

All the Lafaelt Electric products have passed the strict tests in accordance with the IEC international standards, ensuring the reliability of all the products in actual operation. The capacitors of Lafaelt Electric can meet the requirements of different users for power factor correction under relatively harsh gird conditions.

It is used in reactive power compensation device to transmit reactive power to the grid, improve system power factor, reduce line and transformer loss, and play a role in voltage supporting.

It is used in harmonic filtering devices, the capacitors also can be used in conjunction with reactors in series to filter out grid harmonics and purify the grid.

Lafaelt power factor correction capacitor is eco-friendly and self-healing.

The capacitor core is vacuum-packaged in a cylindrical aluminum shell using Esi technology, which effectively improves the partial discharge inception voltage of the product.

The capacitor has the features of self-healing and super long working life.

Lafaelt capacitor adopts a unique vacuum heat setting and vacuum infusion technology, by using a special insulating medium as the internal filler of the capacitor, it can achieve a real dry effect, thus there will not be any fire risk caused by oil leakage and play a good role in eco environment and security.

The capacitor is designed with a self-healing medium structure. Once the medium breaks down, the unique self-healing feature can basically restore the original characteristics of the capacitor in a very short time.

Each of the capacitor has been configured with a discharge model, which can ensure that the terminal voltage drops below 50V within 60s after powered off.

After a special high vacuum technology and a long drying and dehumidification process of the active components, the capacitor is filled with a special insulating medium. The inner shell is full of protective insulating medium and sealed, then conduct strict leak-proof testing. The production process avoids partial discharges (corona discharges) and improves the long-term stability of the capacitor.

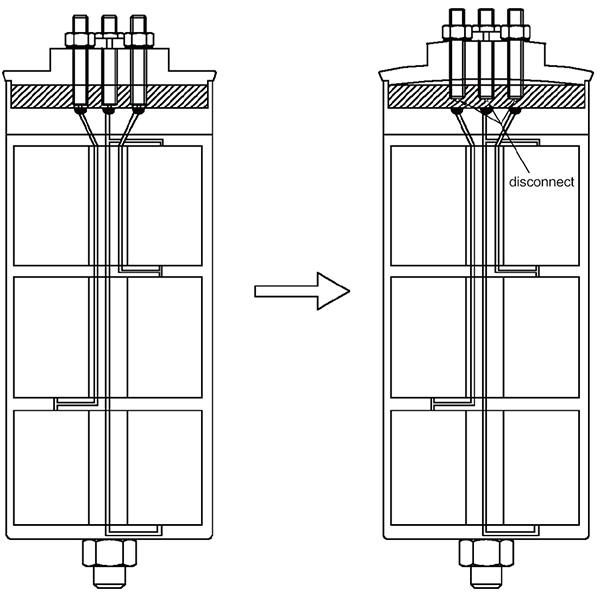

The capacitor outer shell is designed with an explosion-proof structure. Once the internal pressure increases due to non-self-healing breakdown of the capacitor, it can be deformed through the shell to drive the built-in explosion-proof device to work, so that the faulty capacitor can be automatically disconnected from the grid, and effectively prevented from bursting.

The capacitors should be installed away from heat source, such as the reactors, thyristor heatsink, etc., and avoid direct sunlight.

The capacitors should be installed at the bottom of the cabinet with a lower temperature as far as possible, and the installation distance between adjacent capacitor shells are ≧30mm

Try to install in layer with the reactors. When they must be installed on the same layer, the distance between the shell of capacitor and reactor should be ≧100mm

Implementing Standards | |

IEC60831-1-2014IEC60831-2-2014 | |

Application Environment | |

Temperature | Lowest -40°C, highest +55°C |

Altitude | ≦2000m (Higher altitude can customized) |

Relative Humidity | ≦95% |

General Parameters | |

Rated Voltage(Un) | Above 1000V |

Rated Frequency(Fn) | 50/60Hz |

Rated Capacity(Qn) | 5 ~ 40kvar |

Capacity Accuracy | 0-3% |

Phase Unbalance | ≦1.03 |

Dielectric Loss | < 0.2W/Kvar |

Withstanding Voltage | ≧2.15Un/10S |

Limit of shell pressure resistance | 3000V/60S |

Self-discharge Performance | ≦60S |

Operating Parameters | |

Overvoltage | 1.35Un |

Maximum Surge | 100ln |

Overcurrent | 1.8~3ln |

Reliability,resistance to explosion | |

Reliability | Running at rated voltage and normal working condition, the annual average capacity loss rate is ≦1% |

Explosion-proof Method | Tensile pressure prevents explosion |

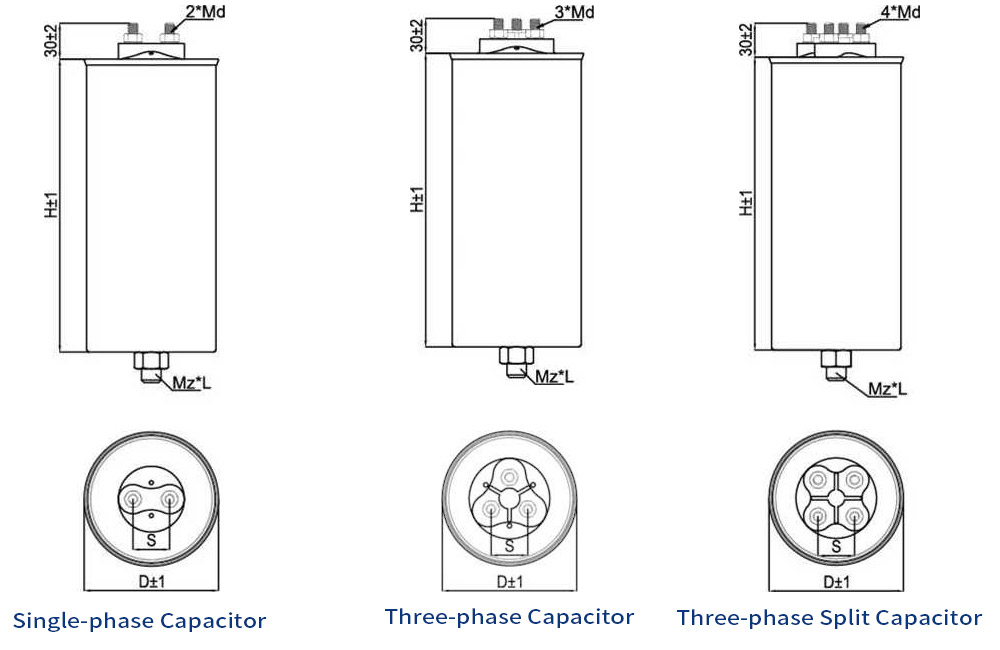

Specification | Rated Capacity | Rated Current | Rated Capacitance | Dimensions (mm) | |||

Model | Kvar | A | UF | D x H | S | Md | Mz x L |

LCP250-6.7 | 6.7 | 26.7 | 340 | 76×245 | 30 | 2-M8 | M12×16 |

LCP250-8.3 | 8.3 | 33.2 | 423 | 90×245 | 30 | 2-M8 | M12×16 |

LCP250-10 | 10 | 40.0 | 510 | 90×245 | 30 | 2-M8 | M12×16 |

LCP250-13.4 | 13.4 | 53.6 | 682 | 106×245 | 30 | 2-M8 | M16×25 |

LCP250-15 | 15 | 60.0 | 764 | 106×245 | 30 | 2-M8 | M16×25 |

LCP250-16.7 | 16.7 | 66.8 | 851 | 116×245 | 30 | 2-M8 | M16×25 |

LCP250-20 | 20 | 80.0 | 1019 | 116×245 | 30 | 2-M8 | M16×25 |

LCP280-6.7 | 6.7 | 23.9 | 272 | 76×245 | 30 | 2-M8 | M12×16 |

LCP280-8.3 | 8.3 | 29.6 | 338 | 90×245 | 30 | 2-M8 | M12×16 |

LCP280-10 | 10 | 35.7 | 406 | 90×245 | 30 | 2-M8 | M12×16 |

LCP280-13.4 | 13.4 | 47.8 | 544 | 106×245 | 30 | 2-M8 | M16×25 |

LCP280-15 | 15 | 53.6 | 609 | 106×245 | 30 | 2-M8 | M16×25 |

LCP280-16.7 | 16.7 | 59.6 | 678 | 116×245 | 30 | 2-M8 | M16×25 |

LCP280-20 | 20 | 71.4 | 812 | 116×245 | 30 | 2-M8 | M16×25 |

LCP300-6.7 | 6.7 | 22.3 | 237 | 76×245 | 30 | 2-M8 | M12×16 |

LCP300-8.3 | 8.3 | 27.7 | 294 | 90×245 | 30 | 2-M8 | M12×16 |

LCP300-10 | 10 | 33.3 | 354 | 90×245 | 30 | 2-M8 | M12×16 |

LCP300-13.4 | 13.4 | 44.6 | 474 | 106×245 | 30 | 2-M8 | M16×25 |

LCP300-15 | 15 | 50.0 | 531 | 106×245 | 30 | 2-M8 | M16×25 |

LCP300-16.7 | 16.7 | 55.7 | 591 | 116×245 | 30 | 2-M8 | M16×25 |

LCP300-20 | 20 | 66.7 | 708 | 116×245 | 30 | 2-M8 | M16×25 |

Specification | Rated Capacity | Rated Current | Rated Capacitance | Dimensions (mm) | |||

Model | Kvar | A | UF | D x H | S | Md | Mz x L |

LCP250-20-F | 20 | 26.7 | 1019 | 116×290 | 30 | 4-M8 | M12×16 |

LCP250-30-F | 30 | 40.0 | 1529 | 136×290 | 30 | 4-M8 | M16×25 |

LCP280-20-F | 20 | 23.8 | 812 | 116×290 | 30 | 4-M8 | M16×25 |

LCP280-30-F | 30 | 35.7 | 1219 | 136×290 | 30 | 4-M8 | M16×25 |

LCP300-20-F | 20 | 22.2 | 708 | 116×290 | 30 | 4-M8 | M16×25 |

LCP300-30-F | 30 | 33.3 | 1062 | 136×290 | 30 | 4-M8 | M16×25 |

Specification | Rated Capacity | Rated Current | Rated Capacitance | Dimensions (mm) | |||

Model | Kvar | A | UF | D x H | S | Md | Mz x L |

LCP440-15 | 15 | 19.7 | 247 | 106×245 | 35 | 3-M8 | M16×25 |

LCP440-20 | 20 | 26.2 | 329 | 116×245 | 35 | 3-M8 | M16×25 |

LCP440-25 | 25 | 32.8 | 411 | 116×290 | 35 | 3-M8 | M16×25 |

LCP440-30 | 30 | 39.4 | 493 | 116×290 | 35 | 3-M8 | M16×25 |

LCP480-10 | 10 | 12.0 | 138 | 90×245 | 30 | 3-M8 | M12×16 |

LCP480-15 | 15 | 18.0 | 207 | 106×245 | 35 | 3-M8 | M16×25 |

LCP480-20 | 20 | 24.1 | 276 | 116×245 | 35 | 3-M8 | M16×25 |

LCP480-25 | 25 | 30.1 | 346 | 116×290 | 35 | 3-M8 | M16×25 |

LCP480-30 | 30 | 36.1 | 415 | 116×290 | 35 | 3-M8 | M16×25 |

LCP480-33.4 | 33.4 | 40.2 | 461 | 136×290 | 35 | 3-M8 | M16×25 |

LCP480-40 | 40 | 48.1 | 553 | 136×290 | 35 | 3-M8 | M16×25 |

LCP525-15 | 15 | 16.5 | 173 | 106×245 | 35 | 3-M8 | M16×25 |

LCP525-20 | 20 | 22.0 | 231 | 116×245 | 35 | 3-M8 | M16×25 |

LCP525-25 | 25 | 27.5 | 289 | 116×290 | 35 | 3-M8 | M16×25 |

LCP525-30 | 30 | 33.0 | 347 | 116×290 | 35 | 3-M8 | M16×25 |

LCP525-40 | 40 | 44.0 | 462 | 136×290 | 35 | 3-M8 | M16×25 |

LCP850-15 | 15 | 10.2 | 66 | 106×245 | 35 | 3-M8 | M16×25 |

LCP850-20 | 20 | 13.6 | 88 | 116×245 | 35 | 3-M8 | M16×25 |

LCP850-25 | 25 | 17 | 110 | 116×290 | 35 | 3-M8 | M16×25 |

LCP850-30 | 30 | 20.4 | 132 | 116×290 | 35 | 3-M8 | M16×25 |

* Dimensional changes will not be notified, subject to the actual delivered products. If you have any questions, please contact Lafaelt.

| Classify | Title | Download |

|---|---|---|

| Esicap PFC Capacitor Operation Manual V4.0 |

Leave your contacts and our engineers will help you to find the solution you are looking for.

Hi! Welcome back.

How are you doing?

Let s talk! We’ll provide the perfect solution for you!

Lafaelt Electric is focusing on complete solutions for power quality and energy management. We have excellent quality in designing, researching, producing and manufacturing on Active harmonic filter, Static VAR generator(SVG), Power capacitor, Reactor, Thyristor switch, Dynamic voltage restorer and Active voltage conditioner.

Sales Center Add: No. 1, Xinyan Road, Xinwu District, Wuxi, Jiangsu Province, China

Factory Add:No.1, Xinyan Road, Xinwu District, Wuxi City, Jiangsu Province, China