With voltage sag and complete voltage loss protection function.

Strong overload capacity, support DC start.

Has perfect anti-DC backflow and DC output control function.

System intelligence, modularization, easy operation and maintenance

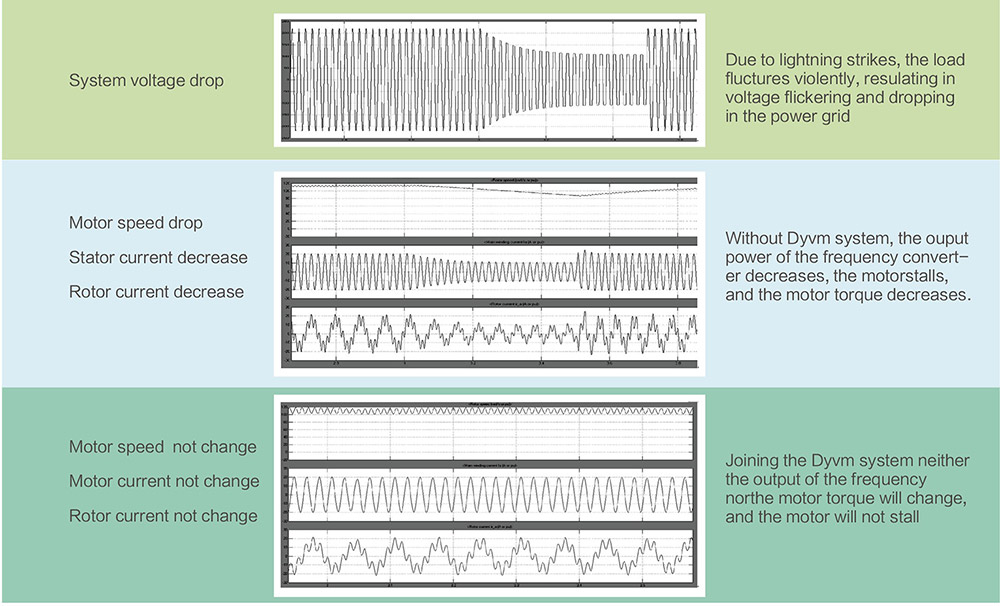

Voltage sags are generally caused by failures of power grids and substation facilities or sudden large changes in loads. In some cases, there may be two or more consecutive sag or swell. If the voltage sag is too long, the equipment will stop abnormally, a large number of products will be scrapped, the yield rate will be greatly reduced, and huge economic losses will be caused.

Industry | Equipment |

Semiconductor and integrated circuit | Tin plating, etching, and coating equipment, wafer cutting machines, mounting machines, cleaning equipment, electroplating equipment, etc. |

Textile | Tension control equipment, winding and unwinding of wire drawing machines, etc. |

Metallurgy and smelting | Main rolling line, flying shear, fan and water pump, roller table, blast furnace winch, elevator door machine and hoisting |

Petroleum and petrochemical | Fans, pumps, air compressors, pumping units |

Building materials | Full line of cement, ceramics and glass production lines |

Cigarette factory | Cigarette shreds, cigarette packaging |

Papermaking | Supporting fan water pump, pulp, high-speed paper making, paper cutter, rewind machine |

Municipal, water supply and sewage treatment | Water pump |

1. With voltage sag and complete voltage loss protection function

2. Strong overload capacity, support DC start

3. System intelligence, modularization, easy operation and maintenance

4. With perfect short circuit protection function

5. Perfect equipment self-test function

6. Has perfect anti-DC backflow and DC output control function

7. Remote control, telemetry, signaling, and adjustment functions can be realized

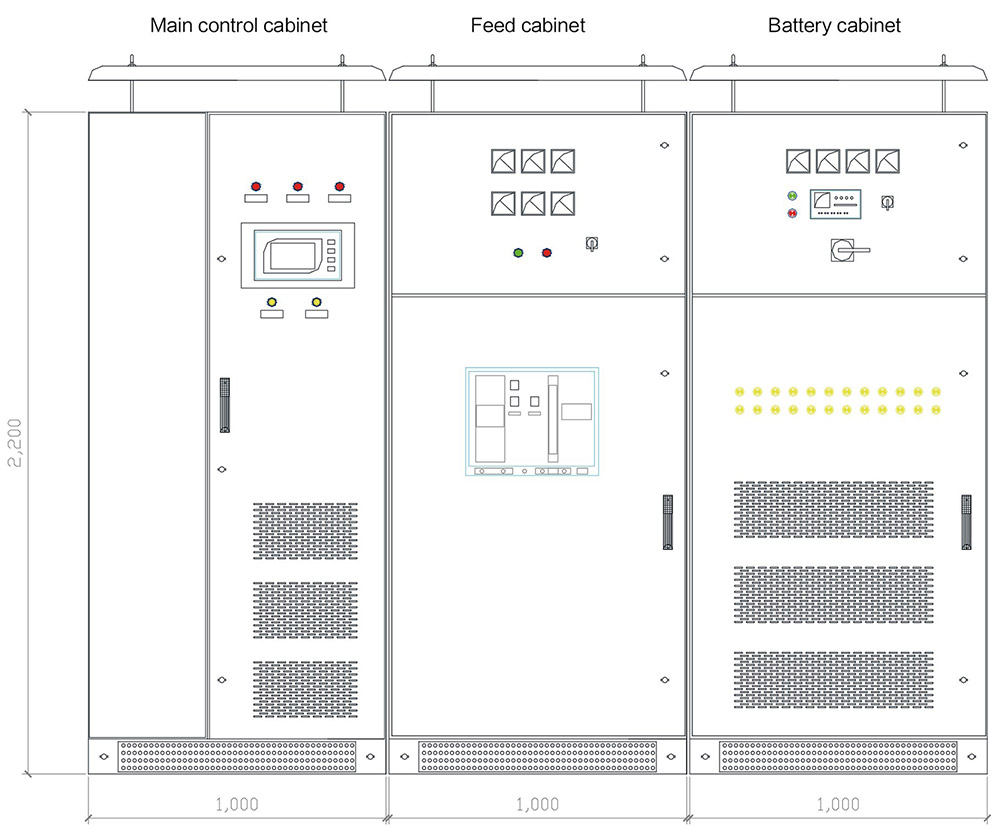

AC input voltage: | 0-380V 3 AC +20% | |

Power supply frequency: | 50-60Hz | |

DC output voltage: | 110V-540V DC | |

Cabinet efficiency: | 98% | |

Power factor: | 0.95 | |

Protection function: | Protection of short-circuit, overload, input overvoltage, and over-temperature | |

Protective class: | IP20 | |

Operation display: | Displayed in Chinese and English | |

Compliant standards: | EC 73/23/EEC | |

Cooling method: | Natural cooling | |

Operation envirnement temperature: | -10°C~45°C | |

Support time: | The input voltage is 70% of the rated voltage | 3min (can be customized) |

The input voltage is 40% of the rated voltage | 5s (can be customized) | |

The input voltage is 0, cut off | 20ms (can be customized) | |

Relative humidity: | <90%, no gel | |

Noise: | ≤60dB | |

Protocol: | Modbus 485 | |

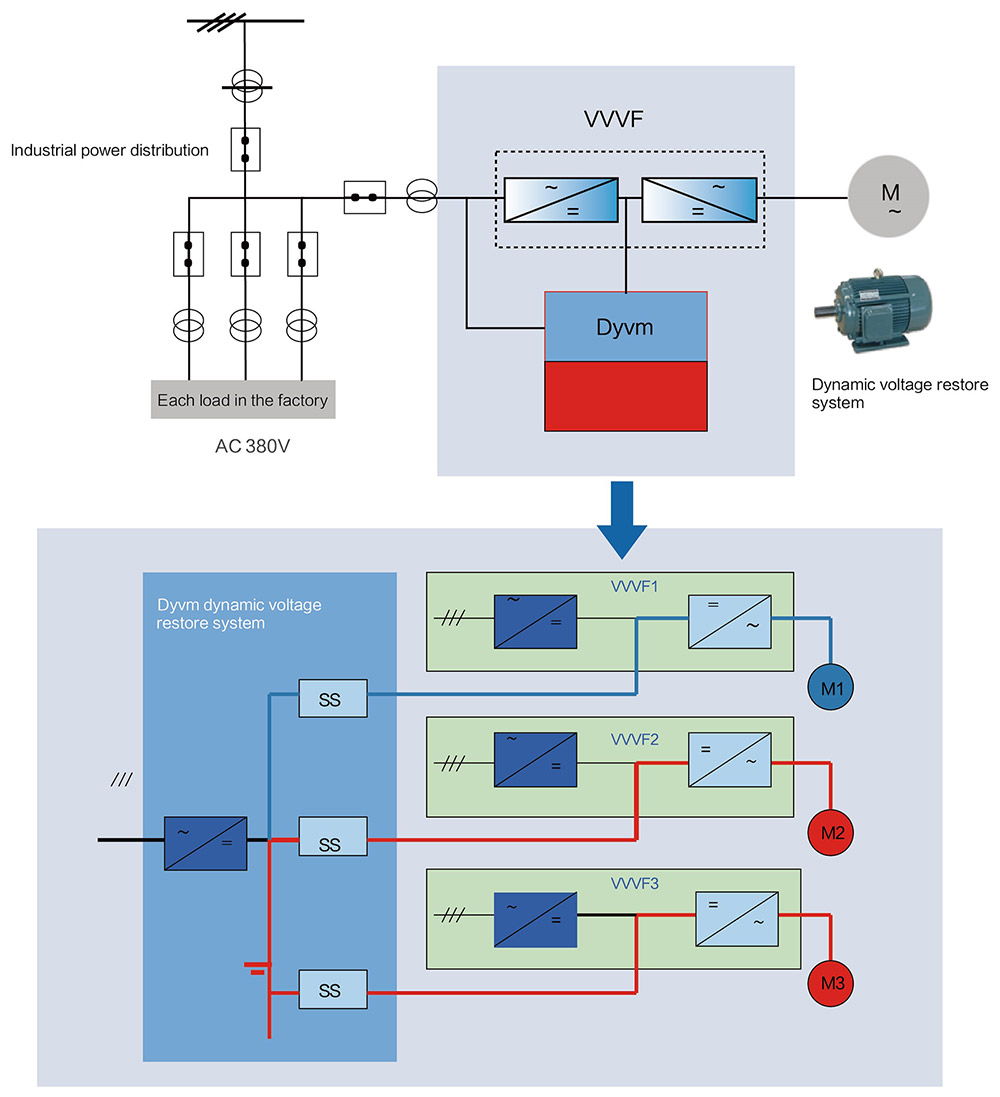

Schematic Diagram of Supporting System for Multiple Frequency Converters Parallel

| Classify | Title | Download |

|---|

Leave your contacts and our engineers will help you to find the solution you are looking for.

Hi! Welcome back.

How are you doing?

Let s talk! We’ll provide the perfect solution for you!

Since its establishment, Lafaelt Electric has focused on comprehensive solutions for power quality and energy management. It has excellent quality in designing, researching, producing and manufacturing.

Sales Center Add: 2nd Floor, No. 268, Tongxie Road, Changning District, Shanghai, China

Factory Add:No. 79, Qunxing Road, Xinwu District, Wuxi City, Jiangsu Province, China