Real-time measurement, alarm and attenuation monitoring

Capacitor service life prediction.

Operation history record

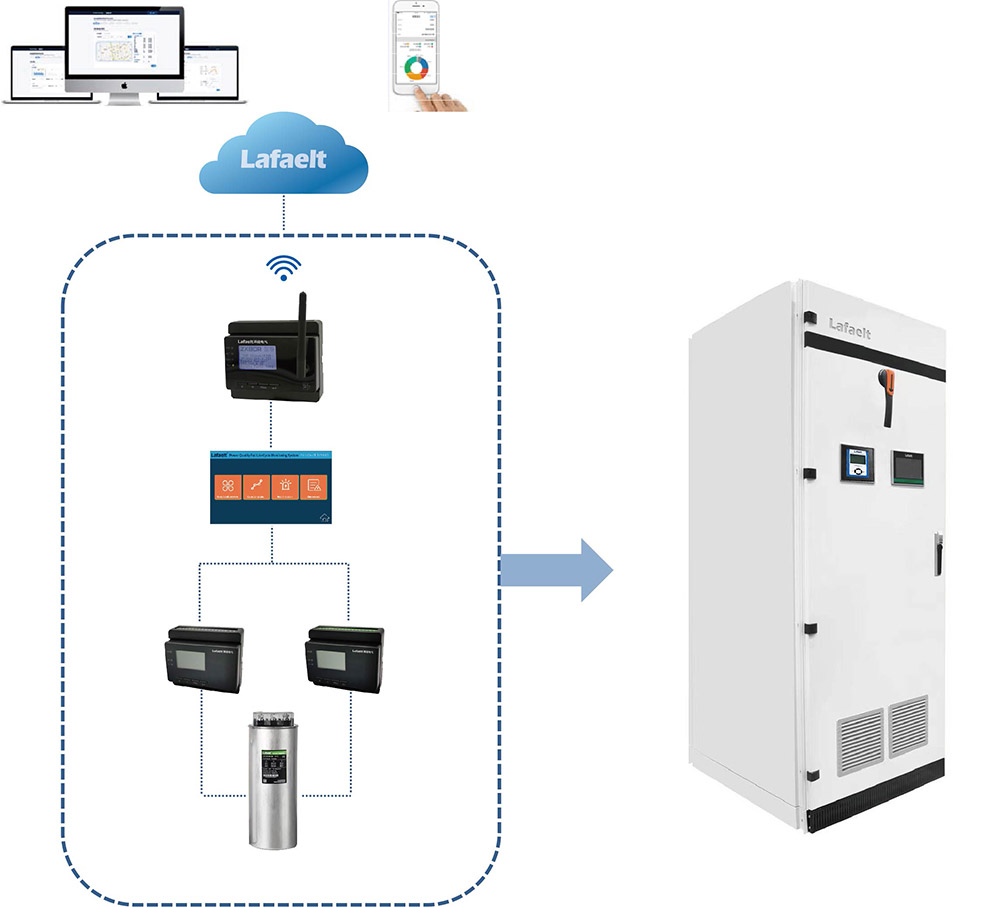

In view of the current situation, Lafaelt developed the whole life cycle monitoring system of reactive power compensation device. Through the self-developed smart capacitor monitoring module, real-time collection of capacitor switching current and real-time temperature information, monitoring the remaining capacity and switching status of each capacitor bank. Built-in advanced edge computing model to calculate the attenuation degree and service life of capacitor bank, to achieve the whole life cycle management of reactive power compensation device. The system can monitor the real-time output capacity of the whole cabinet, the cumulative running time of capacitor bank, real-time temperature and other information, when the capacitor current and temperature are abnormal, the system will alarm in real time, to avoid the occurrence of major electrical safety accidents such as explosion and fire, and truly realize preventive maintenance.

The traditional reactive power compensation device is equipped with a smart capacitor monitoring module and a health status display smart screen to form a full life cycle monitoring system for reactive power compensation. Through the intelligent communication server, the collected data and fault alarms are transmitted to the cloud platform in real time, and users can view the real-time status and fault alarm information at any time, helping users realize intelligent unattended operation and maintenance management.

LRTS-D device is mainly used for nonlinear loads such as large-scale welding equipment, driving cranes, and frequency conversion devices. It needs to obtain a large amount of reactive power from the grid in real time. The reactive power demand of new energy vehicles, integrated circuits and other industries changes rapidly, causing severe flicker and needs fast reactive power compensation.

Measuring the total compensation capacity, the current value of each capacitor, the real time value of temperature, etc., so that users know the real-time situation

Accurately predict the remaining capacity of each capacitor through edge calculation to ensure that the power factor compensation is adequate.

Based on the operation data of each capacitor, the built-in algorithm model accurately calculates the service life of the capacitor

Comprehensively analyze the balanced use of each capacitor bank to avoid the frequent use of a single bank

Realize the abnormal alarm of life, attenuation, temperature of each capacitor module, and actively push it to the user

The system can record all the operating information, convenient for users to query the history of the operation

System voltage | 200~700V 50Hz |

Rated capacity | 100~480kvar/cabinet (other capacity can be supplied according to needs) |

Compensation mode | Three-phase compensation, single-phase compensation, single and three-phase mixed compensation |

Tuning frequency | 134Hz,189Hz |

Protection class | IP30 (other class can be supplied according to needs) |

Installation site | Indoor |

Isolation level | 3kV/1min |

Discharge time | 50V/1min |

Temperature range | -5℃~+40℃ (the 24-hour average maximum is 35°C, and the annual average maximum is 25°C) |

Manufacture standards | IEC60831,EN60439-1,GB/T15576-2020,JB/T9663-1999RA |

Cabinet color | RAL7035 (other color can be supplied according to needs) |

Digital dynamic reactive power compensation device grouping scheme

Rated voltage 400V/50Hz, SCR switching, 7% filter reactor in series, with phase split compensation, typical combination scheme

Power | Combined Model | (kvar)Circuit Capacity | Controller | Cabinet Dimensaion | |||||||||||

(kvar) | Module 1 | Module 2 | Module 3 | Module 4 | |||||||||||

1a | 1b | 1c | 2a | 2b | 3c | 3 | 4 | 5 | 6 | 7 | 8 | LPF230-12-W | (W*H*D) | ||

180 | LRTS480-180/10-7-D | 10 | 10 | 10 | 10 | 10 | 10 | 30 | 30 | 30 | 30 | LPF230-12-W | 800*2200*1000 | ||

240 | LRTS480-240/10-7-D | 10 | 10 | 10 | 10 | 10 | 10 | 60 | 60 | 30 | 30 | LPF230-12-W | 800*2200*1000 | ||

270 | LRTS480-270/10-7-D | 20 | 20 | 20 | 10 | 10 | 10 | 60 | 60 | 30 | 30 | LPF230-12-W | 800*2200*1000 | ||

300 | LRTS480-300/10-7-D | 20 | 20 | 20 | 20 | 20 | 20 | 60 | 60 | 30 | 30 | LPF230-12-W | 800*2200*1000 | ||

420 | LRTS480-420/12-7-D | 20 | 20 | 20 | 20 | 20 | 20 | 60 | 60 | 60 | 60 | 30 | 30 | LPF230-18-W | 800*2200*1000 |

480 | LRTS480-480/12-7-D | 20 | 20 | 20 | 20 | 20 | 20 | 60 | 60 | 60 | 60 | 60 | 60 | LPF230-18-W | 800*2200*1000 |

Note: When the reactive power compensation cabinet is mixed compensation, in order to ensure heat dissipation, it is recommended to divide it into main and auxiliary cabinets if the capacity of a single cabinet exceeds 480kvar.

Series 14% filter reactor with phase split compensation, model LRTS525-300/10-14-D, LRTS525-480/12-14-D, etc.

| Classify | Title | Download |

|---|

Leave your contacts and our engineers will help you to find the solution you are looking for.

Hi! Welcome back.

How are you doing?

Let s talk! We’ll provide the perfect solution for you!

Lafaelt Electric is focusing on complete solutions for power quality and energy management. We have excellent quality in designing, researching, producing and manufacturing on Active harmonic filter, Static VAR generator(SVG), Power capacitor, Reactor, Thyristor switch, Dynamic voltage restorer and Active voltage conditioner.

Sales Center Add: No. 1, Xinyan Road, Xinwu District, Wuxi, Jiangsu Province, China

Factory Add:No.1, Xinyan Road, Xinwu District, Wuxi City, Jiangsu Province, China